GreenForces delivers customized design results that ensure cost-effective, low time-to-market solutions through a highly motivated group of technology companies and Michigan Technological University. GreenForces is driven by strong design principles, highest levels of quality and ethical business practices.

Learn more and watch the video at www.gsengineering.com

Mechanical Engineering

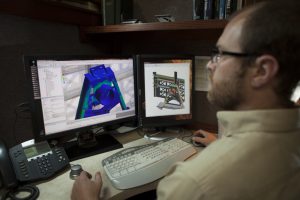

- Fully supported Computer Aided Design (CAD) and Computer Aided Engineering (CAE) departments staffed by advanced degreed Professional Engineers (PEs)

- Design software packages supported: Creo Elements (Pro/E)/Windchill PDM, CATIA/SmarTeam PDM, Siemens NX/TeamCenter PDM, SolidWorks, AutoCAD and other customer-required packages

- Analysis software packages supported: ANSYS, Altair Hyperworks (Hypermesh/Optistruct), MathCAD, MATLAB and other simulation software

- Full life cycle engineering support

- Advanced product development

- Lightweight product and structural design

- Component and system integration

- Energy and heat transfer design and analysis

- Interior system integration

- Technical data package support (ASME Y14.100, ASME Y14.34)

- Fatigue life prediction

- Fracture mechanics

- Advanced casting and forging

- Metal matrix composite

- Carbon composite

- Advanced aluminum alloy

Electrical Engineering

- CAN-BUS/CAN-AERO integration and programming (A815)

- Avionics integration and validation

- Microprocessor and FPGA/CPLD programming

- Aircraft and vehicle power system design

- EMI/EMC design (HIRF, lightning, grounding/bonding)

- Automated test equipment

- Printed circuit board development and design

- Electrical circuit load analysis

- 3D harness routing and connector integration

- RF Coupler and Beam Forming Design

- Antenna Design and Placement

- 2D electrical schematics

- Design software packages support: CadSoft Eagle, Altium PSPICE, Boardstation, DxDesigner, MATLAB Simulink, and MathCad, and others

Quality & Manufacturing Engineering

- Design for Manufacturing (DFM) supported by Certified Quality Engineers (CQE), Quality Auditors (CQA), and Weld Inspectors (CWI)

- AS9100C Supplier management

- Develop and implement quality planning to support manufacturing

- Design manufacturing and inspection fixtures